-in-aqueous-based-paints.jpeg)

The Importance of Defoamers (Antifoams) in Aqueous-Based Paints

-in-aqueous-based-paints.jpeg)

In the world of water-based (aqueous) paints, where performance, finish quality, and production efficiency matter the most, one silent enemy often lurks behind production lines and application sites: foam.

Foam

may seem harmless, but for paint manufacturers, applicators, and end users,

uncontrolled foaming can lead to a host of performance and aesthetic problems.

That’s where defoamers, also known as antifoams, play a crucial role.

Understanding

Foam in Aqueous Paints

Foam

forms when air gets trapped in the paint during manufacturing, filling,

stirring, pumping, or even during application by brush, roller, or spray. The

main reasons foam formation is more severe in aqueous paints include:

- · High surface tension of water

- · Presence of surfactants (from dispersants,

wetting agents, emulsifiers, etc.)

- · Mechanical agitation during production and

application

Foam,

if left untreated, can lead to:

- · Surface defects like craters, pinholes, and

fish eyes

- · Volume inconsistencies in packaging

- · Reduced gloss and poor film appearance

- · Inconsistent colour development

- · Application failures, especially in spray

paints or roller coats

What

Are Defoamers / Antifoams?

Defoamers

are specialty additives designed to control, suppress, or eliminate foam during

production, storage, and application of paints. They act by disrupting the foam

structure, causing air bubbles to collapse or preventing them from forming in

the first place.

How

Defoamers Work: The Chemistry Behind It

Most

foam structures are stabilized by surfactants. Defoamers work by:

- · Spreading rapidly on foam surfaces

- · Reducing surface elasticity

- · Disrupting foam lamellae (bubble walls)

- · Promoting bubble coalescence and rupture

A good defoamer remains inactive until needed, then acts quickly and does not adversely affect the final appearance or stability of the paint.

Types

of Defoamers for Aqueous Paints

Different

formulations of aqueous paints demand different defoamer chemistries. Common

types include:

|

Type |

Features |

Typical Use |

|

Mineral oil-based |

Economical, broad defoaming

action |

Architectural paints,

primers |

|

Silicone-based |

High efficiency at low doses, long-lasting |

High-gloss emulsions, industrial coatings |

|

Silicone-free polyols

/ polyethers |

Non-silicone option,

better for recoating |

Clear coatings,

sensitive topcoats |

|

Emulsion type

defoamers |

Easy to incorporate, good for high-speed

production |

Pigment pastes, concentrated systems |

Key

Considerations for Selecting a Defoamer

Choosing

the right defoamer is more than picking a chemical - it’s about balancing performance

with side-effect management:

- · Effectiveness at Low Doses: High efficiency

with minimal input level

- · Compatibility: No adverse impact on color

acceptance, gloss, or stability

- · Persistence: Long-term foam control from

manufacturing to final application

- · Recoatability: No surface defects or poor

inter-coat adhesion

- · Low VOC & Eco Compliance: Especially

important for green label or eco-certified paints

When

to Add Defoamers in Paint Manufacturing?

Strategic

addition points include:

- · During grinding stage: To

control foam during pigment dispersion

- · During let-down stage: For

persistent foam suppression in the final paint

- · In packaging: To

avoid filling foam during canning

- · Some modern defoamers are designed to withstand

even post-application foaming during roller or spray applications.

Field

Application Problems Solved by Defoamers

Without

effective defoamers, end users might encounter:

- · Bubbles trapped inside the paint film

- · Reduced film build per coat

- · Poor levelling and aesthetic defects

- · Sagging or cratering due to trapped air release

after application

Professional painters often notice that paints with well-formulated defoamers flow better and deliver smoother finishes.

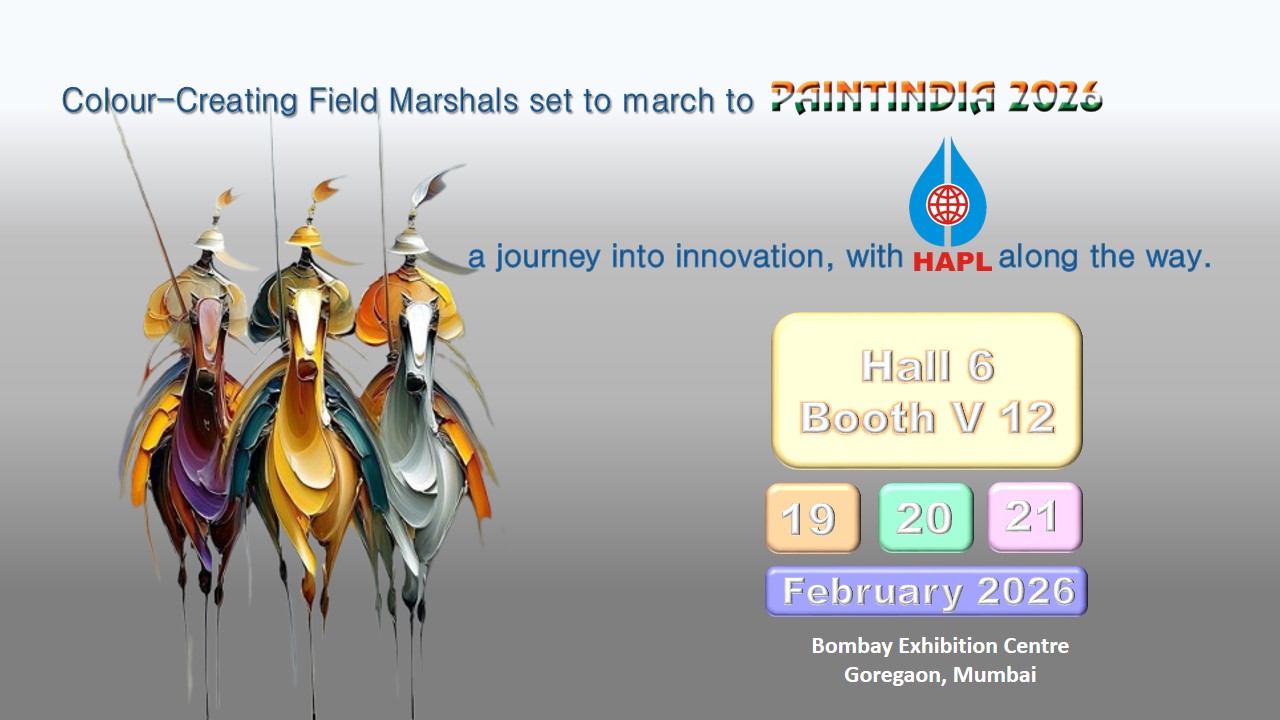

Harmony Group: Delivering Defoaming Solutions Worldwide

We understand that defoaming needs differ across geographies, formulations, and application methods. Our wide portfolio of defoamers - ranging from mineral oil-based, silicone-based, to silicone-free options; caters to diverse industry needs from architectural paints to industrial coatings. With experience serving clients across Asia, Africa, GCC, and Europe, we tailor solutions to climate, storage conditions, and local performance standards.

From low active content high efficiency defoamers, to high active superior quality defoamers, we have got it all!